Layflat piping is used to extend the reach of drying, dehumidification and ventilation. It is ideal for use on water damage restoration projects with air scrubbers, negative air machines, air changers and dehumidifiers.

Layflat Pipe For Drying And Dehumidifying Water Damage

Layflat ducts are an economical and efficient choice for temporary distribution of clean and dry air. The product is a versatile, lightweight, disposable tube that can be used in both drying, dehumidification, negative air extraction from machinery and air conditioning applications.

For commercial restoration projects, flat ducts are ideal for air distribution or air movement in many applications, such as transferring large amounts of dry air to confined spaces or removing humid air from an affected area or filtering air through a HEPA negative air machine. and exhaustion from the building.

How To Dry A Water Damaged Ceiling

Water-damaged ceilings can be dried with a flat pipe. Layflat tubing expands when inflated by the dehumidifier and is ideal for targeted drying of water damage. In the FLIR thermal camera photo above, you can see the hot, dry air flowing directly into the kitchen ceiling space.

24 Hour Water Damage Restoration Company In The Toronto Area

Restoration mate is a restoration company in Toronto you can trust to provide reliable and comprehensive commercial water damage restoration services. Would you know what to do after discovering water in your ceiling? We can help. If you need fast water cleaning, drying and dehumidification equipment in the Greater Toronto Area, including water damaged ceiling repair and basement flood cleanup, call us FIRST CALL for an emergency.

Lay-Flat Easy To Use

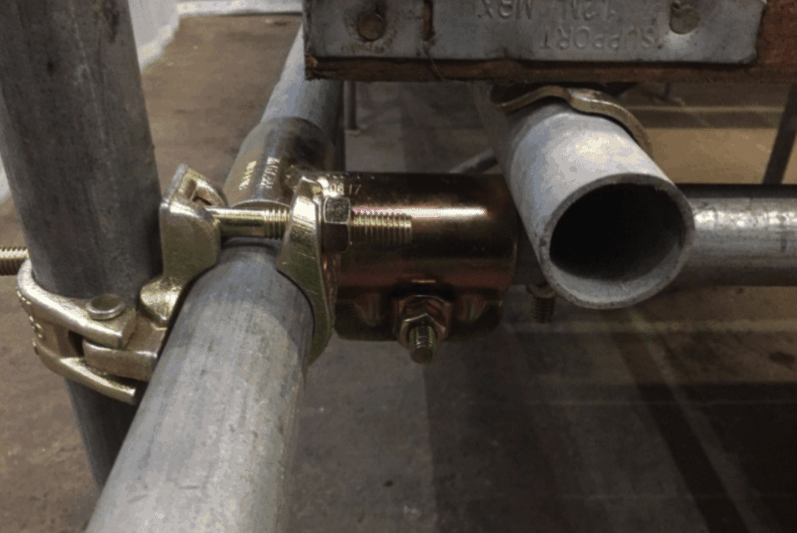

Another great advantage over typical rigid pipes is the way two coil segments are connected or connected to valves and fittings using specially designed toothed couplings. The Lay-Flat hose is fitted over the barbed fitting and is held in place with a stainless steel clamp – which is tightened with a regular wrench. This joining process is extremely quick and easy – taking less than a minute compared to HDPE butt welding or rigid PVC end gluing.

Lay-Flat Hose Vs. HDPE Pipe

It may be obvious that due to the limited availability of Lay-Flat diameter, an operation that requires a pipe diameter of 16” (400 mm) to transport the required volume of solution will choose to install HDPE pipe, the only line that may initially seem like an obvious solution. However, let’s analyze the requirements for installing pipes of this diameter and the alternative solution of using Lay-Flat.

Pipe DN400 HDPE SDR17:

Rated pressure: PN10

Weight: 28 kg / linear meter

Section length: 11.9 meters

Butt welding time: 25 minutes (may change depending on cooling time)